Click Here for the Full Press Release & Additional Product Details

CSF was the first company to release a High-Performance Intercooler for the Porsche 992 911 Turbo & Turbo S back in 2021. Since then, the CSF #8188 has established itself as the benchmark intercooler for the 992 Turbo/S used in the highest horsepower builds in the world. CSF is continually expanding coverage of its industry-leading Porsche cooling lineup. Working with industry partners, CSF was the first to learn the Turbo/S High-Performance Intercooler System fits the 2025+ Porsche 992.2 Carrera models equipped with the 3.0L Turbo Engine (non-Hybrid).

Developed with strategic manufacturing partner PWR and tested under the most demanding motorsport conditions, this Billet Intercooler is the ultimate upgrade for 992 911 Turbo/S & 992.2 3.0T owners looking to maximize performance.

Product Details

Design & Engineering

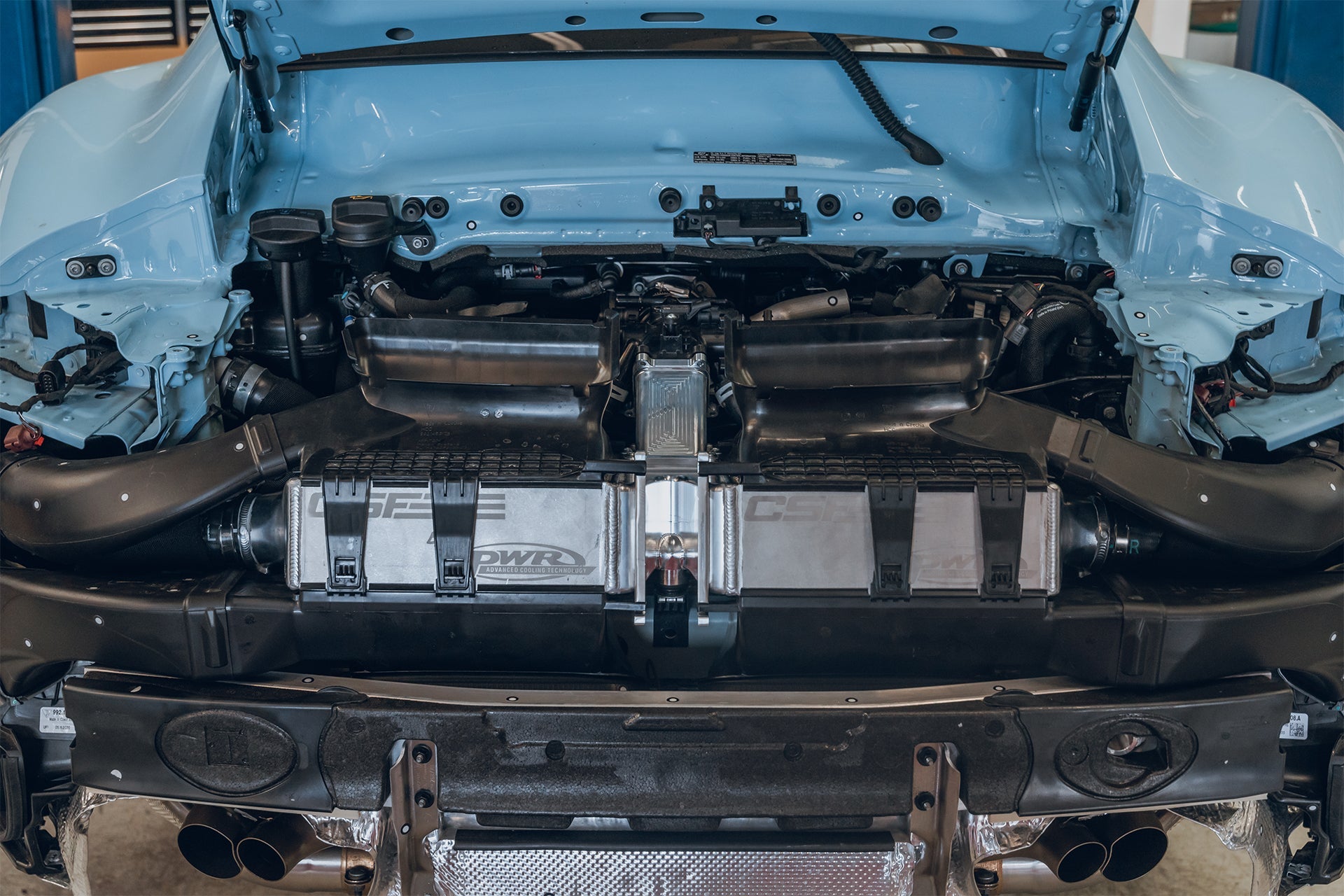

With increased power, also comes higher levels of heat generated by the engine system. This is why an upgraded intercooler system is especially important in a turbo application. The new CSF 992 Turbo/S Intercooler System is a "must have" bolt-on modification, considering placement of the intercooler system on top of the engine.

CSF designed and engineered the intercooler to be a true Plug-and-Play "Drop-in Fit" unit. Utilizing all factory mounting points and ducting, the installation is simple and straightforward.

CSF by PWR VS OEM

| Feature | CSF by PWR | OEM |

|---|---|---|

| # Core Rows | 2 | 1 |

| # Of Tubes | 33 | 17 |

| # Cooling Fin Rows | 34 | 18 |

| Tube Height/Width | 3mm ROLLED TUBE | 7mm |

| Fin Height/Width | 4.85mm | 8mm |

| Core Material | Aluminum | Aluminum |

| Tank Material | Billet Aluminum | Plastic |

| Design | 100% TIG Welded CNC Billet End Tanks |

Crimped w/ Gasket Plastic End Tanks |

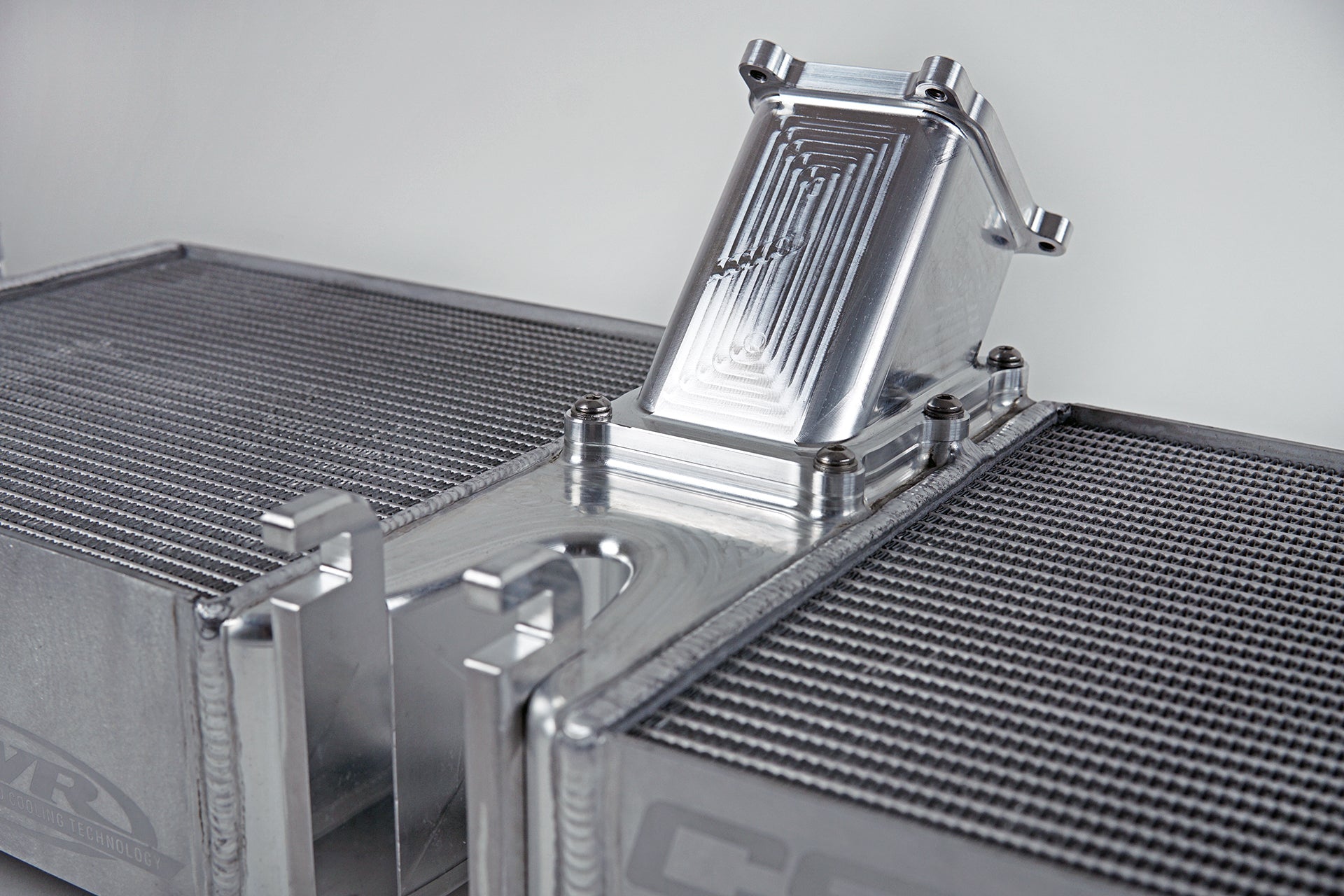

The most important feature of the CSF by PWR Intercooler System is the Formula-1 grade intercooler core. CSF's strategic relationship with PWR has allowed the inclusion of this core, which is unlike any other available in the performance aftermarket.

The intercooler system was originally developed for the Porsche 992 Turbo/S and has been proven on builds making over 1600WHP. The PWR cores eliminate heat soak and lower Intake Air Temperatures (IATs) much more efficiently than traditional Bar & Plate or Tube & Fin designs. These traditional intercooler cores are typically much heavier and/or larger to improve cooling capacity. Because the PWR core is able to achieve greater performance results in a smaller size, CSF was able to design the intercooler system to fit in the stock location using all the OEM hardware, ducts, and shrouds for an easy drop if fit installation.

Like most turbocharged vehicles, the Twin Turbo engines powering the 992 Turbo/S & 992.2 experience high levels of heat soak and progressively increasing IATs even in modestly spirited driving conditions. This results in the ECU pulling engine timing and drastically decreasing power output. The CSF by PWR Intercoolers solve this issue and allow vehicles to perform at optimal levels consistently and for prolonged periods of time.

Test Results

The CSF Intercooler System has undergone rigorous testing and real world validation with leading Porsche builder, tuners, and motorsport teams. Dyno-proven results on Turbo/S applications have shown significant reductions in IATs compared to factory and other aftermarket intercoolers. Companies like Flat 6 Motorsports, ES Motor, GMG Racing, and M-Engineering have all used the CSF system to build everything from 1600+HP roll race monsters to time attack cars. The aftermarket world has definitely proven that the CSF Intercooler is the ultimate 992 cooling solution.

During development, CSF worked with both Jon and Mitch, owners and lead tuners of M-Engineering, to compare the OEM intercoolers vs. CSF's High-Performance Intercooler System on World Motorsports' state-of-the-art wind tunnel dyno.

Jon HebbelnThe CSF intercooler system has proven to be much more efficient throughout the entire rev range, particularly at very high intercooler inlet temperatures (start of the run).

Co-Owner and Engine Calibrator

M-Engineering

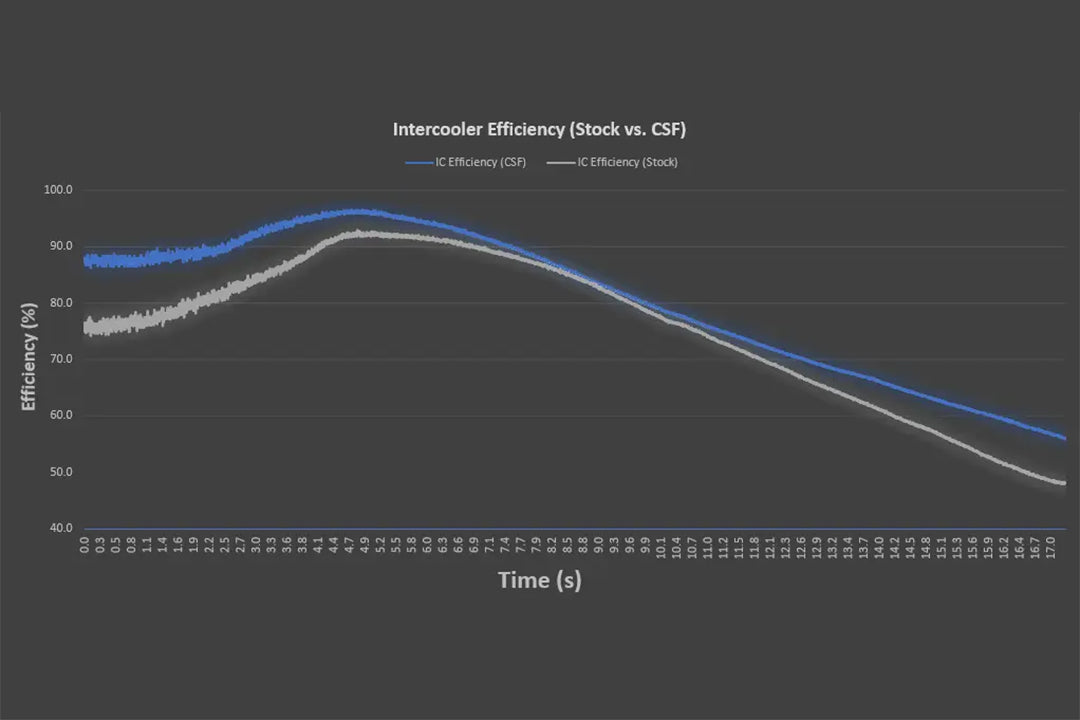

Below are charts of the data from two pulls, one with the stock intercooler system, and one with the CSF High-Performance Intercooler System. These tests started in 4th gear at 2500RPM, went through a shift into 5th, and then to redline.

Intercooler Efficiency*

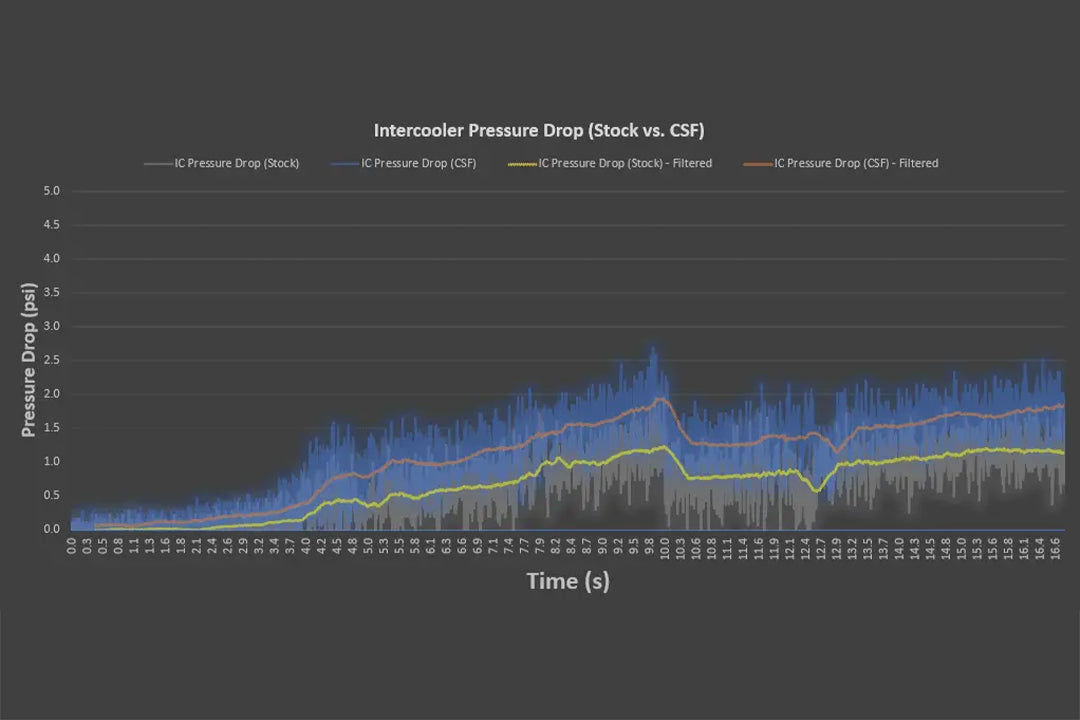

Intercooler Pressure Drop*

*Test results from original tests with a 992 Turbo S for the 2021 Release of the CSF #8188. See Comparative Data Tab for more details

The CSF intercooler system side-by-side comparison to the OEM, shows better results in intake air temperature (IATs) and intercooler efficiency, all while being tested in hotter conditions.

Due to the larger and more efficient cores, the CSF intercooler system displayed a slightly higher level of pressure drop with a range of .5 to 1 psi more than the OEM system throughout the dyno test. This is generally to be expected with more surface area and more drag. Tuning can compensate for this slight change in pressure drop as well as provide maximum performance output. Increased boost pressure is the best way to take advantage of increased efficiency that the CSF by PWR High-Performance Intercooler System provides.

CNC Machined Billet End Tanks

As with CSF's other products produced through our PWR partnership, this Intercooler system features 100% TIG-welded machined billet aluminum end tanks. This is a very significant upgrade compared to the OEM crimped plastic composite end tanks.

1/8 NPT Ports

In addition to being aesthetically pleasing, the increased strength improves longevity and durability on high-performance vehicles. OEM plastic/composite end tanks have been known to crack under heavy boost pressure. The CNC machined billet end tanks are ready to withstand increased boost pressures from bolt-on modifications, higher performance tunes, as well as upgraded turbochargers.

After the initial release, CSF added three 1/8 NPT Ports for Methanol Injection, Boost monitoring, Nitrous, etc. This feature was in high demand by builders, tuners, and end users.

Comparative Data

Industry Leading Dyno Testing by M-Engineering

Working with both Jon and Mitch, owners and lead tuners of M-Engineering, to compare the OEM intercoolers vs. CSF's High-Performance Intercooler System on World Motorsports' state-of-the-art wind tunnel dyno

Below are charts of the data from two pulls, one with the stock intercooler system, and one with the CSF High-Performance Intercooler System. These tests started in 4th gear at 2500RPM, went through a shift into 5th, and then to redline.

Note: Both tests were completed on the same day with the OEM intercoolers tested first at approximately 9:00 AM with much lower ambient air temperature and density altitude (DA). The CSF intercoolers were tested at approximately 2:00 PM. The stock intercooler run had about 40°F cooler intercooler inlet start temps & 20°F cooler IC outlet temps at the start of the pulls, therefore this data has been normalized for real-world results and a fair comparison. The spike in boost pressure displayed on these graphs is representing the shift from 4th to 5th gear when the throttle closes slightly.

OEM vs CSF Intercooler Efficiency

Jon HebbelnThe CSF intercooler system has proven to be much more efficient throughout the entire rev range, particularly at very high intercooler inlet temperatures (start of the run).

Co-Owner and Engine Calibrator

M-Engineering

The CSF intercooler system (left) side-by-side comparison to the OEM (right), showing better results in intake air temperature (IATs) and intercooler efficiency, all while being tested in hotter conditions. (Orange line on the CSF graph on the left-hand side shows improved performance by approximately 25°F at the end of the 5th gear pull)

OEM vs CSF Intercooler Pressure Drop

Due to the larger and more efficient cores, the CSF intercooler system displayed a slightly higher level of pressure drop with a range of .5 to 1 psi more than the OEM system throughout the dyno test. This is generally to be expected – more surface area, more drag – but with increased cooling efficiency, which the CSF intercooler system provided. Tuning can compensate for this slight increase in pressure drop as well as provide maximum performance output, which can take advantage of the efficiencies and higher performance that the CSF by PWR High-Performance Intercooler System provides.

992 Turbo S, tuned by M-Engineering – Mods are catless downpipes, tuned on E30 fuel. After installing the CSF intercoolers + retune, increase of ~16 WHP and ~60 WTQ.

Proven performance requires proper and thorough testing – Behind-the-scenes picture of the 750WHP M-Engineering Turbo S getting many sensors installed to validate the performance of the CSF by PWR Intercooler System before being released to the public.

CSF vs the Competition

CSF has had a lot of success with our CSF by PWR Intercooler System for the 992 Turbo/Turbo S. Having been available for a year longer and hundreds of units sold, our competition did their best to catch up. When Competitor W released their Intercooler kit and CSF received a lot of inquiries as to how they compare. Below are some key feature differences and comparison explanations to help you make an educated decision.

| Feature | CSF by PWR | Wagner | OEM |

|---|---|---|---|

| # Of Tubes | 33 | 18 | 17 |

| Core Rows | 2-Row | 1-Row | 1-Row |

| Tube Height | 3mm Rolled Tube | ~6mm | 7mm |

| Fin Height | 4.85mm | ~6mm | 7mm |

| Core Design | F1 Grade Core | Tube & Fin | Tube & Fin |

| Construction/Design | 100% Tig Welded CNC Billet End Tanks |

Tig Welded Cast End Tanks |

Crimped w/ Gasket Plastic End Tanks |

Key Differences:

- The CSF Intercooler uses Formula 1 grade cores from PWR. The PWR Core offers much better air flow and cooling capacity than a traditional Tube & Fin design like the ones found on the Competitor W System. The Competitor W kit comes with the carbon shrouds because the intercooler cores are significantly larger (thicker & wider) than the OEM cores. The inlet side of the shrouds has not been increased though so the overall airflow is still limited by the factory rear bumper which was designed to work in conjunction with the OEM shrouds. This means the benefit of a larger core is still limited to a degree. Like most Tube & Fin cores, the Competitor W system relies on size to improve cooling. The end tanks were also revised to accommodate the wider core. The CSF by PWR Intercooler system utilizes the factory shrouds & mounting hardware and is a true drop-in fit replacement. We are able to retain the factory sizing because we use the much more efficient core design from PWR. Retaining the OEM core thickness provides better airflow and cooling efficiency.

- The CSF Intercooler has 2 row cores with 33 tubes (34 rows of cooling fins) while the Competitor W appears to use single row cores with 18 tubes (19 rows of cooling fins) which is only one more than OEM units. The dual row cores and additional cooling tubes/fins from CSF offer additional surface area for cooling. This additional surface area and airflow also improves the coolers ability to recover more rapidly when heat soaked.

- The CSF Intercooler end tanks are made from Billet Aluminum vs the Cast Aluminum end tanks from Competitor W. Billet construction is both stronger and lighter than cast, providing improved durability in high boost applications. Competitor W claims a weight of 9.5 kg (21 lbs) while the CSF cooler weighs in at 9.0 kg (20 lbs). Billet vs Cast of this similar weight will mean the CSF will be a lot stronger and more durable than the Competitor W system.

Data Comparison:

Competitor W only includes a comparison of IAT's between their intercooler and factory. We can do a semi direct comparison with our own data here:

Competitor W data shows the following at max readings:

- Ambient Air Temp Stock/Competitor W = 19°C (66.2°F)

- Charge Air (hot side) Temp = 173.6°C (344.5°F)

- IAT (cold side) Stock = 50.7°C (123.3°F)

- IAT (cold side) Competitor W = 39.8°C (103.6°F)

CSF Data shows the following at max readings:

- Ambient Air Temp Stock/CSF = 22.8°C (73°F) / 23.9°C (75°F)

- Turbo (hot side) Temp = 151.7°C (305°F)

- IAT (cold side) Stock = 87.8°C (190°F)

- IAT (cold side) CSF = 79.4°C (175°F)

Formula: Intercooler Efficiency = (Charge Air (hot side) Temp – IAT (cold side)) / (Charge Air (hot side) Temp – Ambient Air Temp)

Competitor W Data Results:

- Stock IC: (344.5 – 123.3) / (344.5 – 66.2) = 79.5% Efficient

- Competitor W IC: (344.5 – 103.6) / (344.5 – 66.2) = 86.5% Efficient

Overall that is a 7% Efficiency increase. Testing Done in house by Competitor W.

CSF Data Results:

- Stock IC: (305 – 190) / (305 – 73) = 49.6% Efficient

- CSF IC: (305 – 175) / (305 – 73) = 56.5% Efficient

Overall that is a 7% Efficiency increase. Testing done at World Motorsports by M-Engineering (3rd Party)

Conclusion:

Competitor W makes a good system also. However, for almost $500 more and an increase in size of 40%, both systems tested almost exactly the same in efficiency (but CSF uses 3rd party testing to remove doubt as to the validity). The test cars were differently configured, but that should not impact the efficiency results greatly. Competitor W also does not offer any testing in regards to pressure drop like CSF does. Hopefully this helps you make a decision on your preferred product.

Features

- Eliminates Heat Soak and Lowers Air Intake Temperatures (IATs) for Maximum Performance in Race Conditions - Especially Critical Due to Intercooler Placement in Engine Compartment

- Formula-1 Performance Grade Core by PWR (2-Row Core Featuring Rolled Tubes w/ Inner Fins) - 33 Tubes vs. OEM 17 - 3mm Rolled Tube vs. OEM 7mm - 4.85mm Fin Height vs. OEM 8mm

- CNC Machined Billet End Tanks With Integrated Y-Pipe Connection to Throttle Body

- 100% TIG Welded vs. OEM Style Gasket and Crimped Plastic End Tanks for Maximum Durability in High Boost Applications

- OEM Style CNC Machined Inlet/Outlet Connections for Precise Fitment with All OEM Components

- Three 1/8 NPT Ports for Methanol Injection, Boost monitoring, Etc

- Highly Engineered, Lightweight Design - Weighing Only 20 lbs. Total (9.07 kg)

- True Plug-and-Play "Drop-in Fit" Installation

- R&D and Performance Testing by Industry-Leading Porsche Tuning Companies - M-Engineering, World Motorsports, GMG Racing, and Gosha Turbo Tech

- Made in the USA at PWR North America

Applications

| Year Range | Make | Chassis Code | Model | Trim | Engine / Trans / Etc | Notes |

|---|---|---|---|---|---|---|

| 2021-2025 | Porsche | 992 | 911 | Turbo | Turbocharged 3.7L H6 | - |

| 2025 | Porsche | 992 | 911 | Turbo 50 Years | Turbocharged 3.7L H6 | - |

| 2021-2025 | Porsche | 992 | 911 | Turbo S | Turbocharged 3.7L H6 | - |

| 2023-2024 | Porsche | 992 | 911 | Sport Classic | Turbocharged 3.7L H6 | - |

| 2025-2026 | Porsche | 992.2 | 911 | Carrera | Turbocharged 3.0L H6 | 992.2 Only |

| 2025-2026 | Porsche | 992.2 | 911 | Carrera T | Turbocharged 3.0L H6 | 992.2 Only |

| 2025-2026 | Porsche | 992.2 | 911 | Carrera S | Turbocharged 3.0L H6 | 992.2 Only |

| 2025 | Porsche | 992.2 | 911 | Carrera 4S | Turbocharged 3.0L H6 | 992.2 Only |

| 2025 | Porsche | 992.2 | 911 | Targa 4 | Turbocharged 3.0L H6 | 992.2 Only |

| 2025 | Porsche | 992.2 | 911 | Targa 4S | Turbocharged 3.0L H6 | 992.2 Only |

OEM Part Numbers

- Porsche: 992 145 805 G

- Porsche: 992-145-805-G

- Porsche: 992145805G

- Porsche: 992 145 805 N

- Porsche: 992-145-805-N

- Porsche: 992145805N

Warranty

Cooling Systems and Flexibles, Inc. (CSF) warrants CSF’s High-Performance Cooling Systems, under normal use and service, to the original purchaser of the vehicle in which the product was originally installed. For more information and details please visit our Warranty Page

SKU# 8188 Warranty Term: Limited Lifetime Warranty